METAL

bike frame sculpture

Dream to be free and you shall be - K. Desai

Brazing

Braze flux-applied metal with silver and bronze alloys via torch tips with attention to spotting and alignment

BRAZing PREP

Measure metal tube height, angles, and fit on frame fixer

Position metal on C-clasps and wooden slab panels for support, bend metal, and validate metal alignment and angling

Mitering metal with hacksaw and milling machine tooth saw

File residual metal and clean metal with emery cloth and sandblaster to be ready for brazing

DESIGN

Draw metal head designs on vellum paper, apply designs to metal

Cut design-applied metal with jeweler’s saw and meticulously carve with files

BRAZING

1400-1600 degrees F melting point

Silver brazing alloy

Bronze brazing alloy

Torch Tips

Flux

MITERING

Custom measurements, angles, and fit

THE PROCESS: Bike Frame Build

JEWELER’S SAW CUTTING

BRAZING

HACKSAW CUTTING

METAL ALIGNMENT

MILL MACHINE CUTTING

FILING

Design

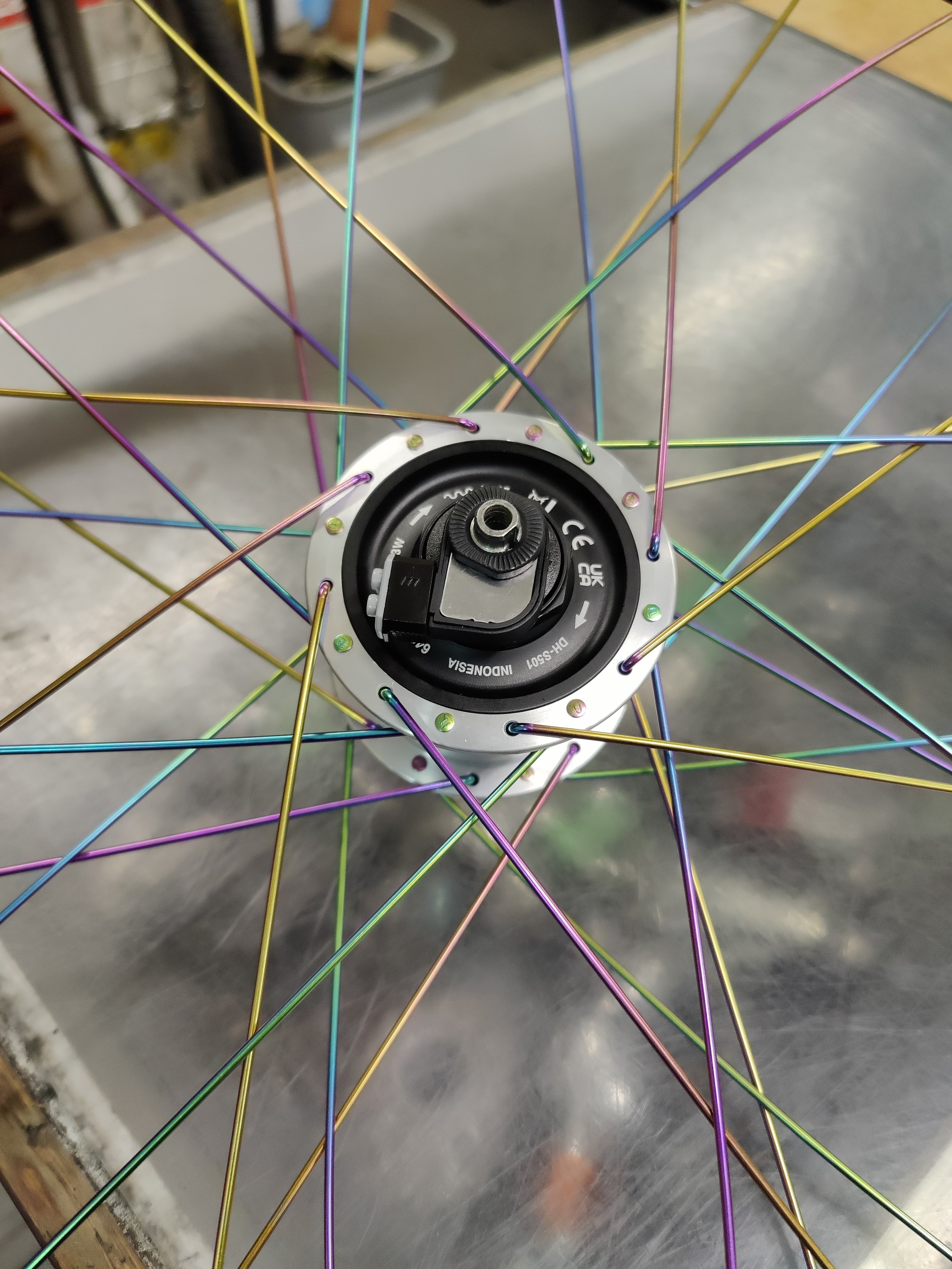

Bike Wheel Build

Components:

Alex Adventure 2 Rim - 26"

Shimano Alfine dynamo hub

Spokes - oil slick color

Spoke Nipples - silver

{building…}